See This Report about Sheroz Earthworks

Fascination About Sheroz Earthworks

Table of ContentsMore About Sheroz EarthworksOur Sheroz Earthworks StatementsThe Greatest Guide To Sheroz Earthworks4 Simple Techniques For Sheroz EarthworksRumored Buzz on Sheroz Earthworks

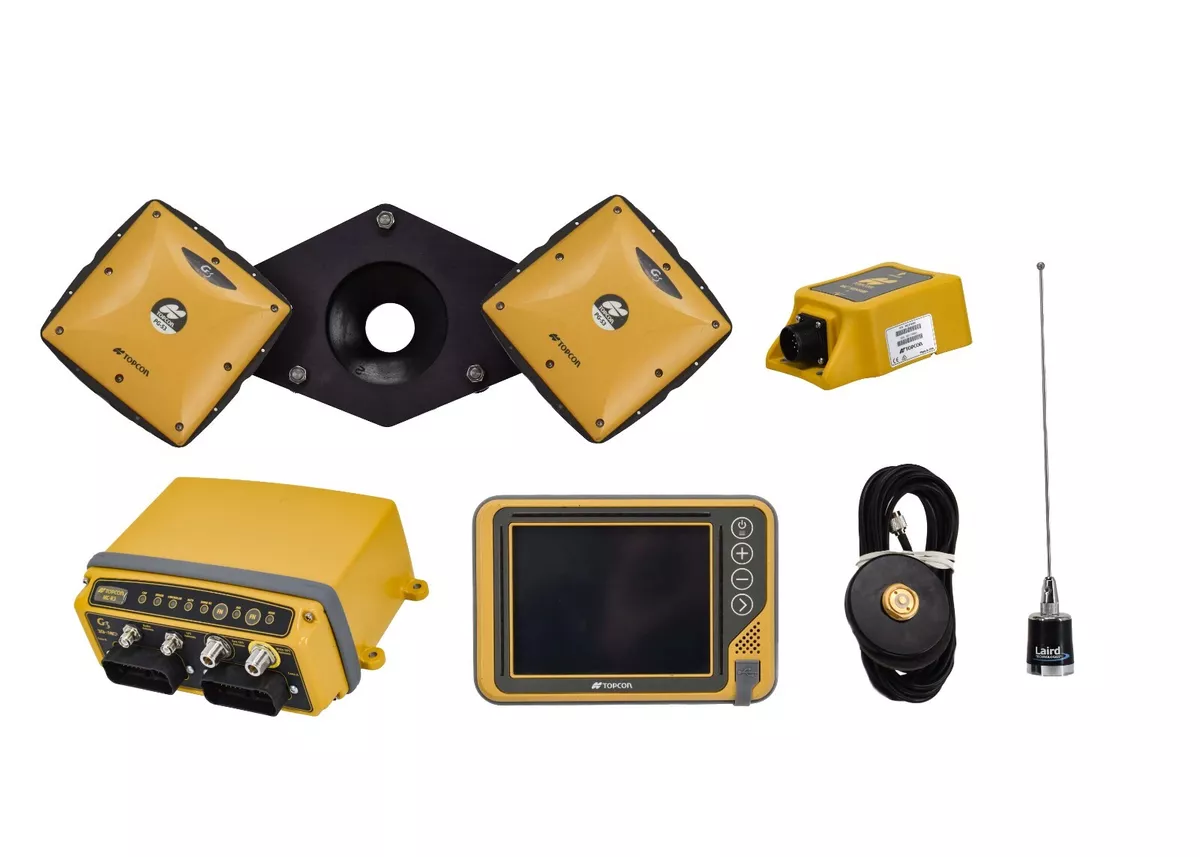

When contractors like Rasch Building and construction execute a grade control system for their dozers, it aids them make fewer blunders when rating. This system continually checks the blade, makes little modifications to the placement of the dozer blade throughout grading and minimizes rework. If the dozer doesn't grade the ground exactly as prepared, the driver can straighten the dozer blade to fix minor errors and make specific modifications to reach the desired grade.When thinking about the acquisition of a quality control system for a dozer, drivers will need training on how to use the system. New operators and skilled experts need to be acquainted with the elements of the 3D grade control system, including the equipment (for instance, the sensors and receivers) and the software application elements.

Sheroz Earthworks Can Be Fun For Everyone

This consists of quality details, elevation data and various other pertinent metrics showed on the LCD screen inside the dozer's taxi. Last, driver training must consist of how to effectively regulate the dozer blade utilizing the 3D grade control system. This assists them understand just how the system changes the blade in response to grade variants.

Product cost savings: If the quality is much more specific, a specialist may require less material for the jobsite. Operators might also lower the requirement for rework and enhance cost financial savings due to labor and materials - https://filesharingtalk.com/members/595996-sherozau. To read more regarding just how to boost jobsite effectiveness with grade control technology, check out the offerings from Trimble and similar companies

Advice and accuracy control, the base components of modern-day maker control for building, have actually proceeded to develop because wide productization began in the mid-1990s. However, the worth suggestion has actually become also sweeter because, with worth being understood past the roi (ROI) of the basic specialists and the total task price for the clients.

Facts About Sheroz Earthworks Revealed

The roots of equipment control stretch back a century. The Historical Building Devices Organization (HCEA) assumes that the A.W. French & Co. "energy " of the 1920s, a crawler-mounted unit that used stringline control, may be the extremely first example and this prior to electronic devices and computer. It was the development of real-time kinematics (RTK) for GPS in the mid-1990s that brought device control as we know it to the building site, and coincidentally to accuracy agriculture.

It moved to precision control, such as blade control, and later on propagated to more classes of mechanized tools, boosted with more sensor combination. The influence on building and agriculture has actually been undeniable: performance gains, much less rework, more efficient handling of materials, much shorter timelines, site safety improvements, and extra - https://yoomark.com/content/home-sheroz. These benefits are as noticeable to customers and drivers as they remained in the early days of adoption, gains from nearly 3 decades of advancement

Automation is not almost speed; it is also about much better control of the lots and stress and anxiety on the equipment and relocating just the ideal quantity of products so as not to position a worry on it. (Photo: CHCNAV) These two activities, as each of our spoken with professionals testify, represent the lion's share of recognized efficiency gains.

The Main Principles Of Sheroz Earthworks

"In addition to the skid guide systems, there are a lot more excavators produced than all the various other equipment kinds integrated," stated Daniel Sass, item supervisor of machine visit this page control at Hemisphere GNSS. "Excavators are the workhorse. And individuals use them differently, and they use other tools to enhance excavators rather in a different way.

Absolutely, by volume it is excavators and small excavators." Numbers assist tell the tale. "In the USA, a minimum of in a three-year period from 2019 to 2022, regarding 253,000 excavators were offered, for which I have pretty trusted information, yet just 61,000 dozers and only 7,000 scrapers," Sass stated

If you most likely to Europe, where they utilize excavators for numerous other tasks, the proportional impact could be greater." Operators can quickly assess the ROI of going electronic for individual tools such as excavators, yet part of the incentive might be that basic service providers are calling for subcontractors to be furnished and prepared to fit into a much more complete electronic site.

"A lot of bigger websites. I would not state everybody mandates it yet, yet that it is growing." "Operator assistance is not just assisting someone cut to quality quicker, but is additionally the very best method to reduce to quality," stated Cameron Clark, earthmoving market supervisor, Trimble Civil Building And Construction. "Exactly how do you move the product? That directly connections into productivity by just moving the material you need to relocate, which likewise relates to less fuel because you can do it much faster." With operator aid, Clark stated, it is not uncommon to see productivity gains of 30% to 40%, despite having inexperienced drivers.

Little Known Questions About Sheroz Earthworks.

There are significant gains to be made in driver assistance for less complicated heavy tools, such as compactors. "Typically a contactor will certainly place a much less skilled driver in the compactor," Clark said. "In hands-on days, to get rid of the possibility of under-compaction and missing places, they 'd produce rather a big overlap, maybe up to 40% of overlap in between courses.